Shredders mainly include 2 types, single-shaft shredders and two-shaft shredders.

Single Shaft Shredder

The WT series single shaft shredder is suitable for recycling wide range of materials.

single shaft shredder is an ideal machine for plastic, paper,fiber, rubber, organic waste and a wide variety of materials.

As per our customers' requirements, such as the input size of the material, capacity and the final output size etc, we could work out a suitable proposal for our clients.

After being shredded by the machine, the output material could be used directly or go into the next step of size reduction.

With the function of Siemens microcomputer control system, it is possible to control automatically start, stop, automatic reverse sensors to protect the machine against over loading and jamming.

Applications:

1. Plastics -- Film, Plastic Barrels, Plastic Barrels, Plastic Pipe

2. Wood -- Timber, Tree root, Wood Pallets

3. White Goods-- TV Shell, Washing Machine Shell, Refrigerator body Shell, Circuit boards

4. Hard Plastic-- Plastic lump, High strength engineering plastic(ABS,PC,PP,and etc)

5. Light Metal -- Aluminum can, Aluminum scrap

6. Solid Waste -- MSW, RDF, Medical waste, Industrial waste

7. Other--Rubber, Textile, fiber& glass products

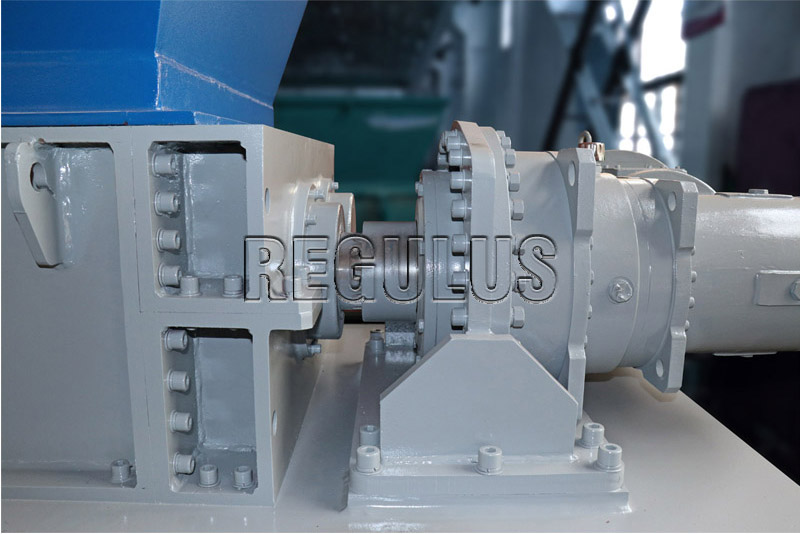

Double shaft shredder

The twin shaft shredders have been designed for a wide array of applications and industries, which is suitable for shredding solid material such as E-waste, metal, wood, plastic, scrap tires, packaging barrel, pallets, etc.

Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction.

Twin shaft shredder is widely used in industry waste recycling, medical recycling, electronic recycling, pallet recycling, municipal solid waste recycling, plastic recycling, tire recycling, paper making industry and etc.

Features

*Slow Speed High Torque Shredding Principle

*Modular Chamber Design with split endplates and bearing housings enables quick access to key components.

*Advanced Adjustable Sealing System for the bearings.

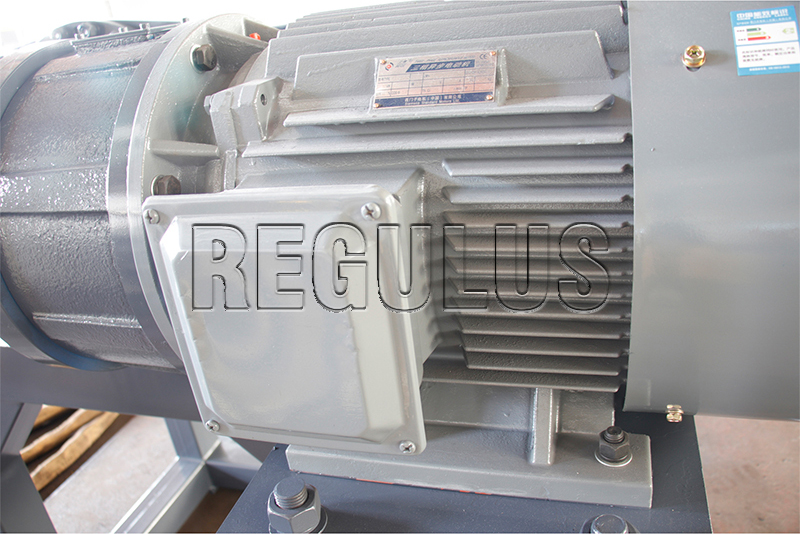

*Stand Alone Electrical Control Panel with Siemens PLC Control System.

*Tested, Approved and Certified to the applicable CE safety standards.

REGULUS is professional manufacturer.Welcome you visit our factory. Regulus Machinery with own manufacture and developed & research team. In order to offer high efficiency after-sales service, our engineers are available to your factory for installation, commissioning, technical guidance and personnel training.

In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

Each component before assembly needs strict control by inspecting personnel.

Each assembly is in charge by a master who has working experience for more than 15 years

Post time: Aug-02-2023