Introduction

Plastic pollution has become a global environmental concern, demanding innovative solutions for effective waste management. The plastic pelletizing line has emerged as a transformative technology in the recycling industry, enabling the conversion of plastic waste into high-quality plastic pellets. This process not only reduces waste volume but also creates valuable raw materials for manufacturing. In this article, we will explore the functionalities, benefits, and applications of the plastic pelletizing line.

Understanding the Plastic Pelletizing Line

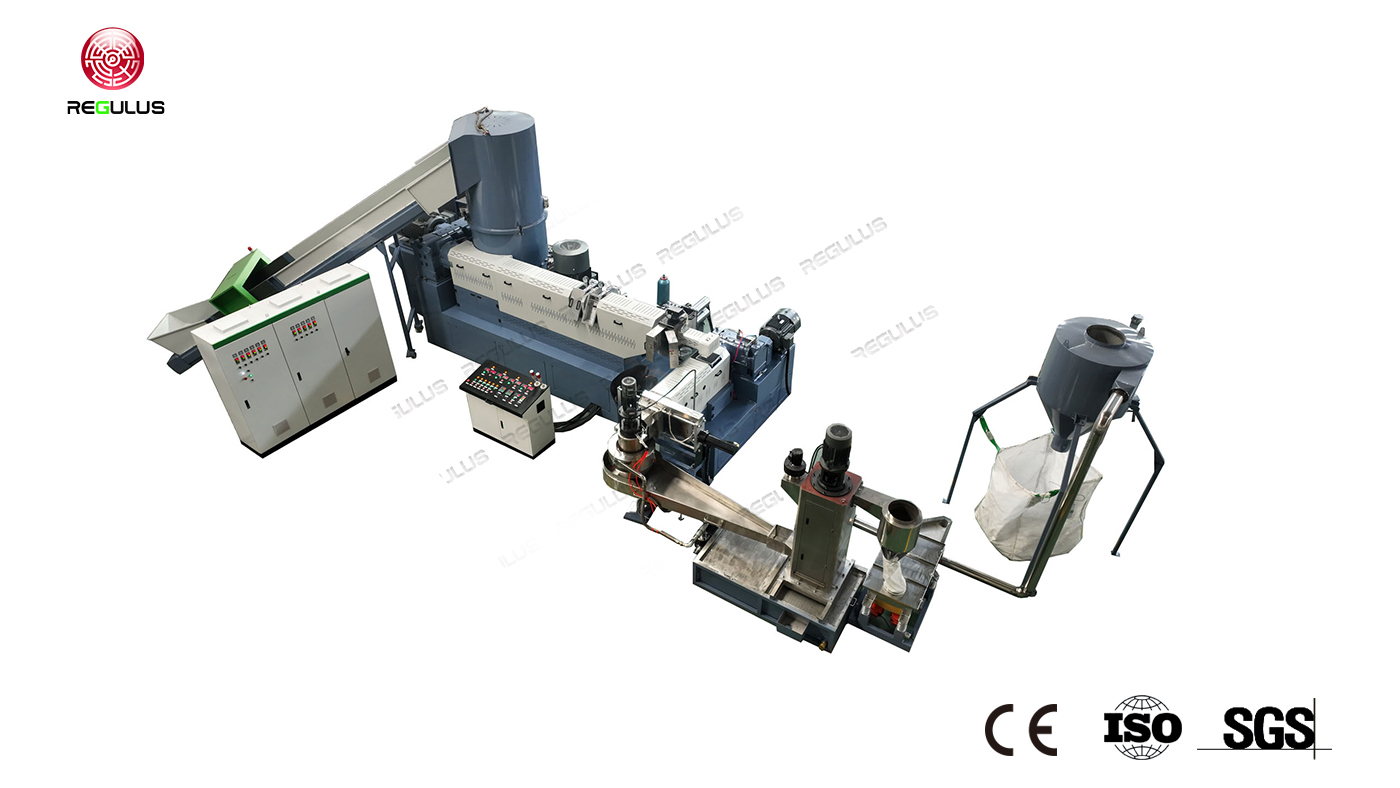

A plastic pelletizing line is a comprehensive system designed to transform plastic waste into uniform plastic pellets through a series of processing steps. The line typically consists of various machines and components, including a shredder or granulator, a conveyor system, an extruder, a pelletizer, and a cooling system. These components work together seamlessly to convert plastic waste into reusable pellets.

Key Processes

Shredding or Granulating: Plastic waste is initially shredded or granulated to reduce its size and ensure uniformity. This step helps in preparing the plastic waste for subsequent processing and improves the efficiency of the pelletizing line.

Conveying: The shredded or granulated plastic is then transported through a conveyor system, which ensures a steady and controlled flow of material into the extruder.

Extrusion: In the extruder, the plastic material is melted and homogenized. The extruder consists of a heated barrel with a screw mechanism that applies heat and pressure to melt the plastic and mix it thoroughly. This process also facilitates the removal of any impurities or contaminants present in the plastic.

Pelletizing: Once the plastic material is molten and homogenized, it is fed into a pelletizer. The pelletizer cuts the molten plastic into uniform pellets of desired sizes. The pellets are then cooled and solidified.

Cooling and Solidification: The plastic pellets pass through a cooling system, where they are rapidly cooled to ensure their solidification. This cooling process ensures the pellets maintain their shape and structural integrity.

Collection and Packaging: The finalized plastic pellets are collected and stored in containers or packaging for further use or sale. The pellets are typically packed in bags or containers to maintain their quality and facilitate their distribution.

Benefits and Applications

Waste Reduction: The plastic pelletizing line significantly reduces the volume of plastic waste. By converting plastic waste into compact and uniform pellets, it optimizes storage, transportation, and handling, leading to reduced landfill usage and better waste management practices.

Resource Conservation: The pelletizing line enables the efficient recovery of resources from plastic waste. The plastic pellets produced can serve as valuable raw materials for manufacturing new plastic products, reducing the reliance on virgin plastic production and conserving precious resources.

Versatility: The plastic pelletizing line is versatile and can process a wide range of plastic materials, including HDPE, LDPE, PVC, PET, and more. This versatility allows for the recycling of various plastic waste streams, catering to the diverse needs of different industries.

High-Quality Output: The pelletizing line ensures the production of high-quality plastic pellets. The process eliminates impurities, contaminants, and irregularities in the plastic, resulting in pellets with consistent size, shape, and composition. These pellets meet industry standards and can be used for a wide range of applications.

Energy Efficiency: The pelletizing process consumes less energy compared to the production of virgin plastic materials. By recycling plastic waste, the pelletizing line contributes to energy conservation and reduces greenhouse gas emissions associated with plastic production.

Environmental Impact: Utilizing the plastic pelletizing line aids in reducing plastic pollution and its environmental impact. By diverting plastic waste from landfills and incineration, it minimizes air and soil pollution. Additionally, recycling plastic waste reduces the extraction of fossil fuels and the energy consumption associated with plastic production.

Conclusion

The plastic pelletizing line has revolutionized the recycling industry, providing a sustainable solution to plastic waste management. By converting plastic waste into high-quality pellets, it offers opportunities for resource recovery and reduces environmental impact. The versatility, waste reduction, resource conservation, and energy efficiency of the plastic pelletizing line make it an invaluable tool in the pursuit of a more sustainable future. As we continue to prioritize responsible waste management and circular economy principles, the plastic pelletizing line plays a crucial role in transforming plastic waste into valuable resources for manufacturing and other applications.

Post time: Aug-02-2023