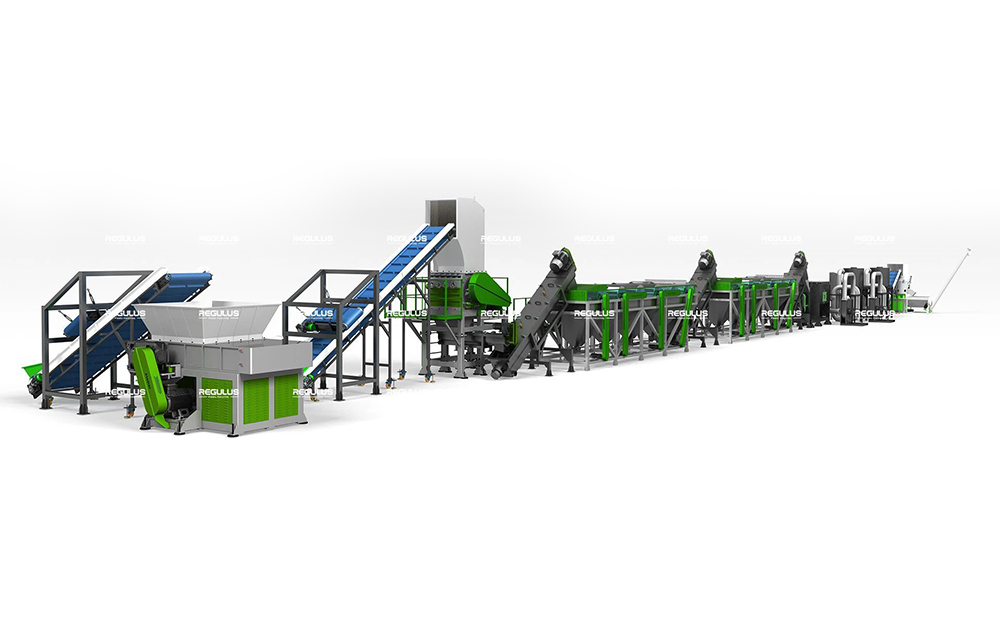

PE PP Plastic Scraps Crusher Washer Dryer Granulator Machine

Product Introduction

The plastic scrap recycling line is the ideal solution for your watse plastic recycling needs. This fully automated washing line takes plastic scraps and turns them into clean, contaminant-free film pieces that can be used to produce high-quality PP / PE granules in the pelletizing process. The pellets produced can then be used to manufacture new plastic products.

To fully wash dirty or soiled plastic scraps, a series of recycling machinery must be used in a specific order. Our standard, high-efficiency plastic scraps washing line offers the most effective way to clean plastic and ranges from an input capacity of 500kg/h upwards to 2,000kg/h. The output capacity is dependant on the volume of contamination within the plastic scraps you’re recycling. While our standard Plastic washing line is sufficient for most facilities, custom setups with additional machinery and increased capacity can be designed for your specific needs.

Product Application

Our waste plastic washing plant are designed for any type of plastic films and plastic bags, bottles and other hard or soft plastic.

An advanced drying solution squeezer pelletizer is a new technology of this recycling system.

Product Features

| 1 | High working efficiency, less energy consumption; high automation, less power. |

| 2 | Long life, machine material is SUS304 stainless steel. |

| 3 | Wet crusher. Crush the plastic with water. SKD-11 blade material. |

| 4 | By multiple friction washing, rinsing washing and hot washing, the dirty such oil contamination and mud can be washed out fully. |

| 5 | Reasonable flowchart design for convenient operation and lower maintenance cost. |

| 6 | Good drying result. Final plastic moisture is less than 3%. |

Product Parameter

| Model | Capacity(KG/H) |

| PEPP-300 | 300kg/h |

| PEPP-500 | 500kg/h |

| PEPP-1000 | 1000kg/h |

| PEPP-1500 | 1500kg/h |

| PEPP-2000 | 2000kg/h |

Product Details

| 1 | Save labor, feeding waste plastic by belt conveyor. |

| 2 | Machine material is SUS304 stainless steel. |

| 3 | Wet crusher. Crush the plastic with water, which can wash plastic preliminary and improve crushing efficiency. |

| 4 | High speed friction washer can separate dirty out by the high rotating speed of the screw. |

| 5 | Floating washer tank separate different plastic by density, the plastic with a density less than water float to the water surface, and the plastic with a density bigger than water sink to the bottom of the tank. |

| 6 | Screw conveyor is used to convey plastic pieces. |

| 7 | Hot washer is used to separate the oil from the plastic. |

| 8 | Dryer, we have centrifugal dewatering machine and squeeze dryer for you choose. |

FAQ

Q: What kind plastic can PE PP plastic scraps crusher washer dryer granulator machine deal with?

A: It can wash and recycle a wide range of soft and hard plastic waste.

For example: agricultural films, greenhouse films, package films and bags, bottles, barrels, box, PE film, HDPE film, LDPE film, agricultural film, PE bags, PP bags, PP woven bags, PP non-woven, PP jumbo bags, HDPE bottles, PP chairs, trays, toys, barrel, drums.

Q: What product capacity per hour can PE PP plastic scraps crusher washer dryer granulator machine deal with?

A: We can make in different size. Main model is 300kg/h, 500kg/h, 1000kg/h, 1500kg/h, 2000kg/h.

Q: Can you make different solutions according to different waste plastic?

A: Yes, we can make different design according to customer’s requirement.