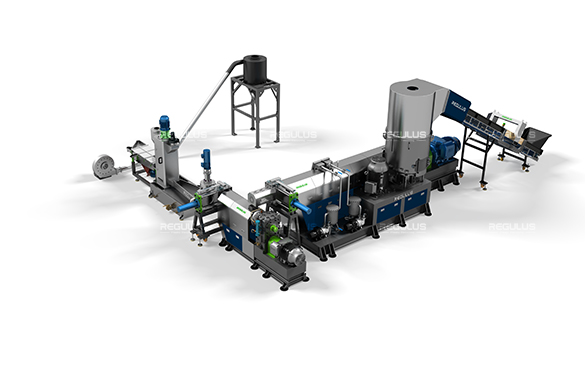

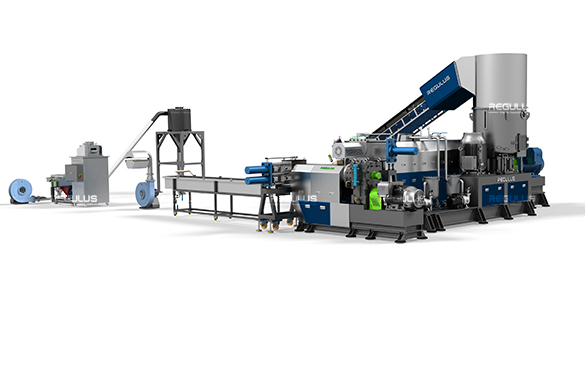

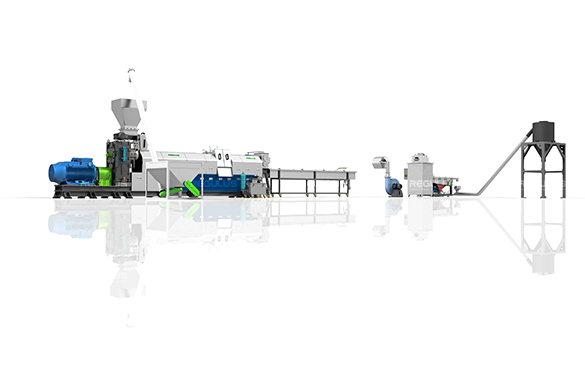

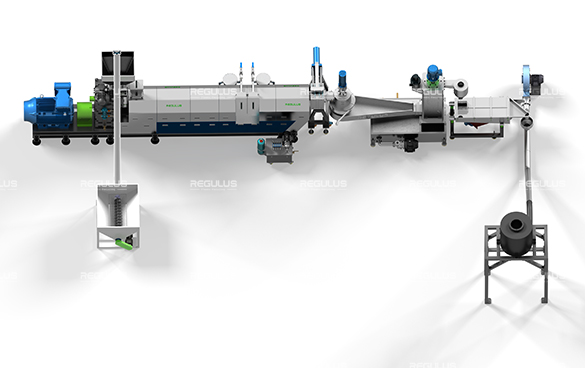

Double section compaction recycling and granulation production line for PE PP PET film

Specifications

| Target Recycled Material | HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS | |||||

| System Composition | Belt Conveyor, Cutting Compactor, Single Screw Extruder, Filtration,Pelletizer,

Water Cooling Device, Dehydration Section,Conveyor Fan, Product Silo. |

|||||

| Material of Screw | 38CrMoAlA (SACM-645), Bimetal (Optional) | |||||

| L/D of Screw | 28/1, 30/1, 33/1, (According to the characteristics of recycling) | |||||

| Heater of Barrel | Ceramic heater or Far-infrared heater | |||||

| Cooling of Barrel | Air cooling of fans through blowers | |||||

| Pelletizing Type | Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing | |||||

| Technical Services | project design, factory construction, installation and recommendations, commissioning | |||||

| Machine Model | Compactor | L/D | Single Screw Extruder | |||

| Volume | Motor Power | Screw Diameter | Extruder motor | Output capacity | ||

| (Liter) | (kw) | (mm) | (kw) | (kg/h) | ||

| XY-85 | 350 | 37 | 85 | 28 | 55 | 150-250 |

| 10 | 22 | |||||

| XY-100 | 500 | 55 | 100 | 28 | 90 | 250-350 |

| 10 | 30 | |||||

| XY-130 | 850 | 90 | 130 | 28 | 132 | 450-550 |

| 10 | 45 | |||||

| XY-160 | 1100 | 110-132 | 160 | 28 | 185 |

650-800 |

| 10 | 55 | |||||

| XY-180 | 1500 | 185 | 180 | 28 | 250-280 |

900-1100 |

| 10 | 90 | |||||

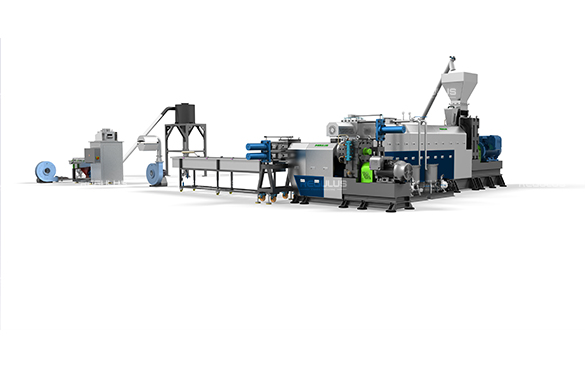

Cutter Compactor Plastic Recycling Pelletizing System

The series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to One step. Applied in the plastics recyclng and pelletizing process. ACSH TM system is a reliable and efficiency solution for plastics film,raffias, filaments, bags, woven bags and foaming materials repelletizing.Lower investment for a high performance machine. It can provide higher output but with lower energy consum ption. Application: PE,PP,PS,ABS,XPS,EPS,PVB.

Feeding

As standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls’ scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor’s room is.

CRUSHING AND COMPACTING

Compactor is equipped with air exhausting device. With the mechanical work of rotor knife and stator knife at the bottom of compactor, the temperature of compactor and material will gradually increase after continuous cutting and friction, and the moisture and dust on the surface of raw material will float to the top of compactor. The device can effectively remove moisture and dust, which will avoid using additional energy consumption to deal with the moisture.This compactor combines pre-heating, pre-dry and size reduction to ensure a fast and stable feeding process.

The Rotatory Blades Of Compactor

The rotating blade and fixed blade cut the material into small flakes. The friction heating generated by the high-speed rotating blades will per-heat and shrink the flakes.

Single Screw Extruder

Our unique design single screw extruder gently plasticizes and homogenizes the materials. Our bi-metal extruder has great anti-corrosion resistant, wear resistant and long life time.

Double Vacuum Degassing Zones

With double vacuum degassing zones, volatile such as micro-molecules and moisture will be removed efficiency to improve the quality of granules, especially suitable for the heavy printed materials.

Plate type screen changer

The Plate type filter is made in a continuous type with two filter plates. There is at least one filter working when the screen is changing.Ring-shaped heater for consistent and stable heating

None-stop Piston Type Filter

1.A regular single-plate/piston double-station screen changer or non-stop double plate/piston four-station can be installed on head of extruder to present significant filtration performance.

2.Long screen lifetime, lower screen change frequency: Long filter lifetime owing to large filter areas.

3. Easy to use and none-stop type: easy and quick screen change and do not need to stop the running machine.

4.Very low operation cost.

Vertical Water Ring Granulation System

1.Self-adjusting pelletiziin head for the best granulate quolity and long uptime thanks to consistently correct blades oressure.

2. RPM of rotatory blades is automatic based on melt extruding pressure.

3.Easy and fast pelletizer blades changeover, without adjustment work saves time.

Horizontal Water Ring Granulation System

1.Self-adjusting pelletiziin head for the best granulate quolity and long uptime thanks to consistently correct blades oressure.

2. RPM of rotatory blades is automatic based on melt extruding pressure.

3.Easy and fast pelletizer blades changeover, without adjustment work saves time.

Vibration Dry

1.Advanced dewatering vibration sieve combing with horizontal-type centrifugal dewatering present high performance dried pellets and lower energy consumption.

2. Assemble sieves: The sieves are installed and fixed by screws instead of welding, so you can change the sieves easily in the future.

Vertical Particle Dehydrator

Specially used for dehydration of plastic plaster water rings and underwater cutting particles,

Vibrating Screen

Used to separate the size of plastic particles