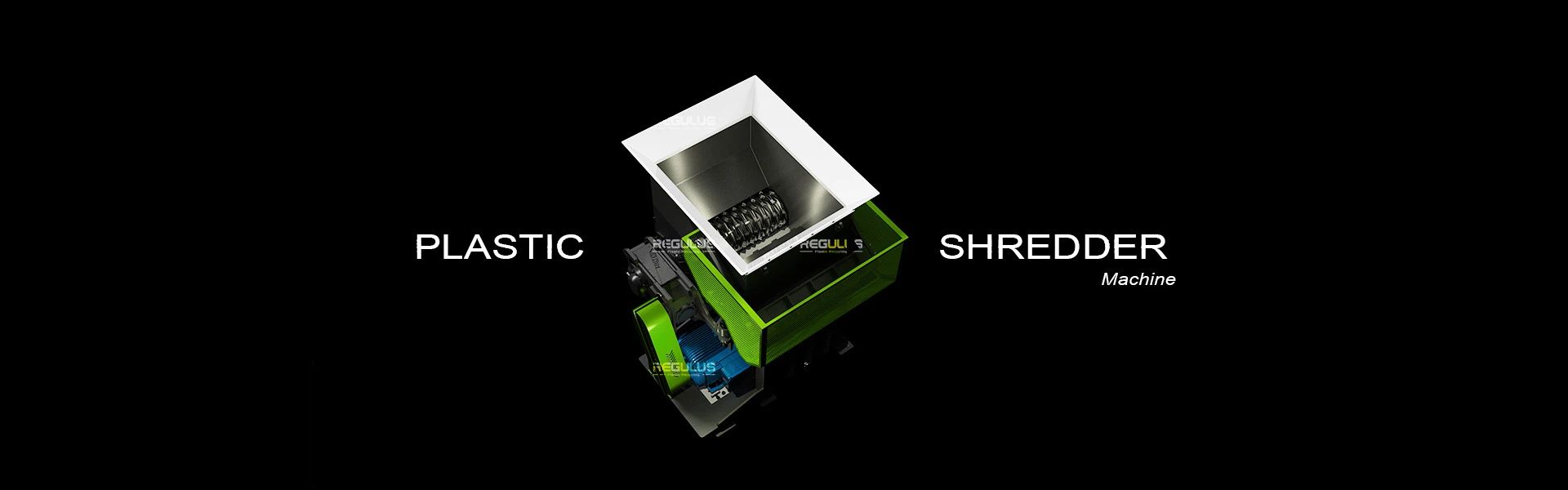

Plastic Shredder and Granulator 2 in 1 Machine

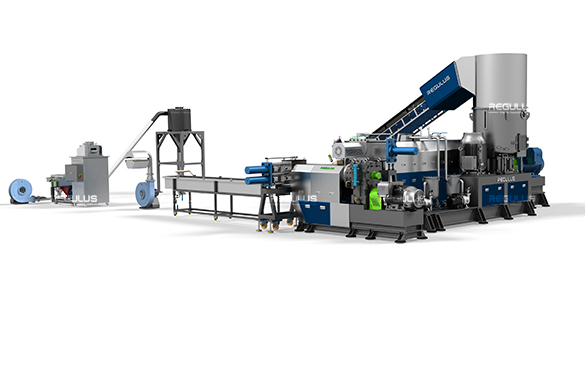

Product Details Design of Plastic Shredder and Granulator 2 in 1 machine

Single shaft shredder and granulator are built together.

Waste plastic shredder and crusher in one machine has two parts in one machine.

The first part is shredding part on the top.

The second part is crushing parts, which is under the shredding part for fine crushing. End product is 8-16mm particle materials.

After shredding, the shredding material goes into crusher machine directly.

Through this shrdedding crushing 2-in-1 machine, customer no need to buy belt conveyor between shredder and granulator, so it can save cost and save space.

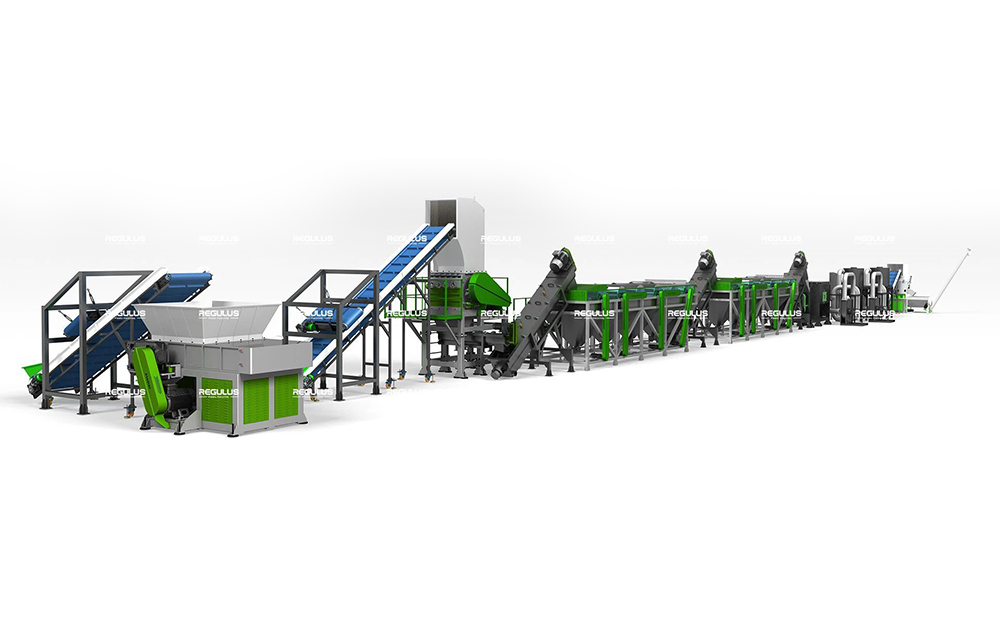

Application of Plastic Shredder and Granulator 2 in 1 machine

The Plastic Shredder and Granulator 2 in 1 machine is an efficient recycling machine for recycling different kinds of waste plastics.

For example, plastic lumps from injection or extrusion machine, plastic pipes, plastic bottles, plastic baskets, barrel, big block material, plastic container, plastic chair, plastic pallet, woven bags, jumbo bags, plastic shells of household appliances(e.g. TV, computer, refrigerator, washer machine, etc).

By equipped with different blades and driving system, the waste plastic shredder and crusher in one machine can be also used for wood, cardboard, copper cables etc.

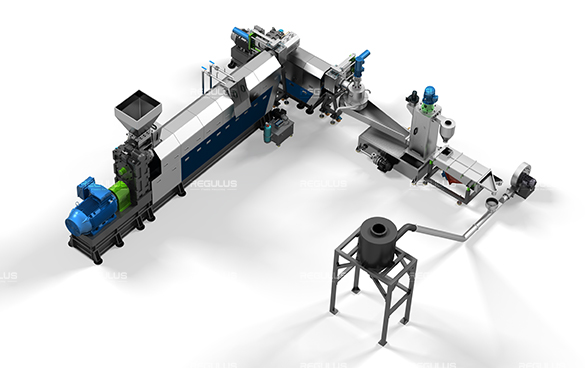

Features of Plastic Shredder and Granulator 2 in 1 machine

Waste plastic shredder and crusher in one machine has the following characters :

| 1 | Save time shredding and crushing function on one machine. Discharged particle materials size can be reused directly |

| 2 | Save space, save cost.

Shredder, crusher and storage system are combined into one machine. |

| 2 | Main shaft is driven by gear reducer , big torque , steady working and low noise |

| 3 | Hydraulic feeding mechanism , independent power unit , strong frame structure |

| 4 | D2 blades for efficient working and long using life

Material strength will decrease sharply after shredding, lower crusher stress, which can improve knife service life. |

| 5 | Hydraulic system with water cooling design |

| 6 | Electrical cabinet with Siemens PLC control system.

Auto control for co-rotation and reversal Auto protection while over-load The machine realize stable and safe working by automaic control of shredder, crusher and storage efficiency |

| 7 | The whole system meets the CE safety standard. |

Main Technical Parameters

| Model | SP2260 | SP4060 | SP4080 | SP40100 |

| A (mm) | 1870 | 2470 | 2770 | 2770 |

| B (mm) | 1420 | 1720 | 1970 | 2170 |

| C (mm) | 650 | 1150 | 1300 | 1300 |

| D (mm) | 600 | 600 | 800 | 1000 |

| E (mm) | 700 | 855 | 855 | 855 |

| H (mm) | 1800 | 2200 | 2200 | 2200 |

| Shredding part: | ||||

| Cylinder Stroke (mm) | 600 | 700 | 850 | 850 |

| Rotor Diameter (mm) | φ270 | φ400 | φ400 | φ400 |

| Shredder Shaft Speed (rpm) | 83 | 83 | 83 | 83 |

| Rotor Blades (pcs) | 26 | 34 | 46 | 58 |

| Fixed Blades (pcs) | 1 | 2 | 2 | 2 |

| Main Motor Power (kw) | 22 | 30 | 37 | 45 |

| Hydraulic Motor Power (kw) | 2.2 | 2.2 | 2.2 | 2.2 |

| Crushing part: | ||||

| Crusher Motor Power (kw) | 15 | 22 | 30 | 37 |

| Crusher Rotary Blades (pcs) | 18 | 18 | 24 | 30 |

| Crusher Fixed Blades (pcs) | 2 | 2 | 4 | 4 |

| Crusher Screen Mesh (mm) | 12 | 12 | 12 | 12 |

| Blower Motor Power (kw) | 2.2 | 3 | 4 | 5.5 |

| Machine Weight (kg) | 2800 | 3600 | 4600 | 5500 |

Detailed Photos